Who took your money from the rubber hose in your warehouse?

Are you disappointed when you found that the hydraulic hose has been damaged when you rush to use it?

Why damaged?

Your hydraulic rubber hose are stored in warehouse, it wasn’t destroyed, and it wasn’t exposed to the sun and wind. Why is it aging and broken?

Improper storage of high-pressure hose can cause various problems and cause you losses.

We all know that many industries are inseparable from high-pressure hoses, such as mine hydraulic supports, coal development, engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and mechanization of various industrial sectors and other industries!

The hydraulic hose pipe is so important, what we should pay attention to when storing?

1.Storage environment and Shelf Life

Storage environment, along with rubber materials, can vary the shelf life limit. Some high pressure hose materials last longer in storage due to inherent resistance characteristics. Other materials require additives during compounding. These additives are eventually consumed by varying environments, even in seemingly ideal storage conditions.

Shelf life is difficult to predict because many variables affect the braided hose. Proper storage precautions can result in five to seven years’ shelf life. Beyond this time, service life can decrease significantly

2.Hose-pipe storage time

Observe the first-in first-out principle,

The storage time cannot exceed the time specified by the manufacturer. If the time is too long, it will cause aging.

If the manufacturer does not have a specified time, please follow the following terms:

-Under 3 years: Can be used without restrictions

-3 to 6 years: visual inspection, test samples at twice the working pressure

-6 to 8 years: full visual inspection, destructive and pulse testing of samples

-Over 8 years: Do not use

3.Storage temperature and humidity

The spiral hose should be stored in a cool and dry place.

Suitable temperature is 15°C, 0°C to 38°C is the acceptable range.

The oil hose should be far way from the heat source.

NO matter what happened, The stored temperatures shouldn’t be above 50°C or below -30°C

In addition, temperature fluctuations during storage may cause premature aging of the flexible hose.

Any rupture of the outer shell will increase with increasing temperature.

Relative humidity should not exceed 70%

4.Ozone

Ozone is an important aging factor

In the storage area, there should be no any ozone generators, such as: mercury lamps, mercury tubes, high-voltage electrical devices, motors, or other devices that can generate sparks or discharges

5. Light

Direct light is the main source of aging.

Do not place it under direct sunlight or strong artificial light.

If there are windows in the storage area, the windows should be covered with a red, orange or white protective film, or opaque packaging should be used on the items.

6.Keep away from chemicals:

Cannot be placed with corrosive products or exposed to the volatile gas of these products.

Such as: fuel, petroleum, grease, volatile, acidic substances, disinfectants, etc.

7.Avoid electric and magnetic fields:

Keep away from equipment that generates electric and magnetic fields. Such as: high-voltage cable, high-frequency generator.

8.placement method

During storage, heavy objects are strictly not allowed to be stacked on the rubber hose body; they should be laid flat. If they need to be stacked, the stacking height should not exceed the limit height specified by the manufacturer, and the steel wire hoses should be frequently “Restack” during storage. At least once every quarter. Should avoid the permanent deformation of the lower hose under pressure.

Can not be squeezing and damage

When storing the hose hydraulic, both ends must be sealed to prevent debris from entering the flexible rubber hose pipe.

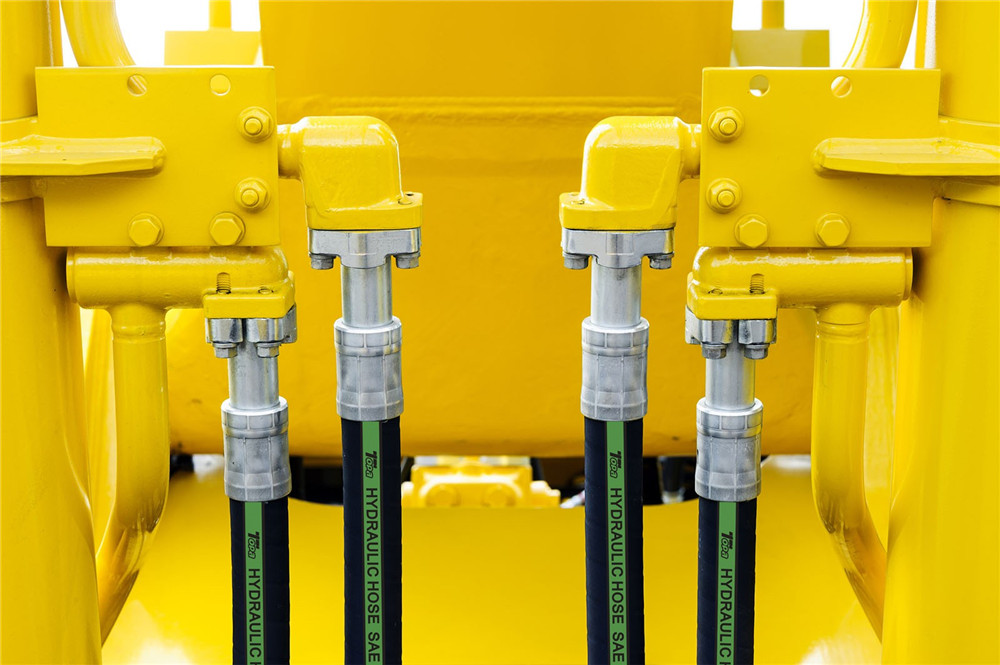

Non-rolled short tube can be made to hang on the shelf (as shown in the figure below, which is stored on site for use.); Avoid contact with sharp hard objects or ground facilities.

9.Storage bending radius

When the high pressure rubber hose is bent, the strain on the outer layer will increase the crack.

Therefore, the smaller the bending radius, the greater the possibility of cracks

Daily warehouse inspection

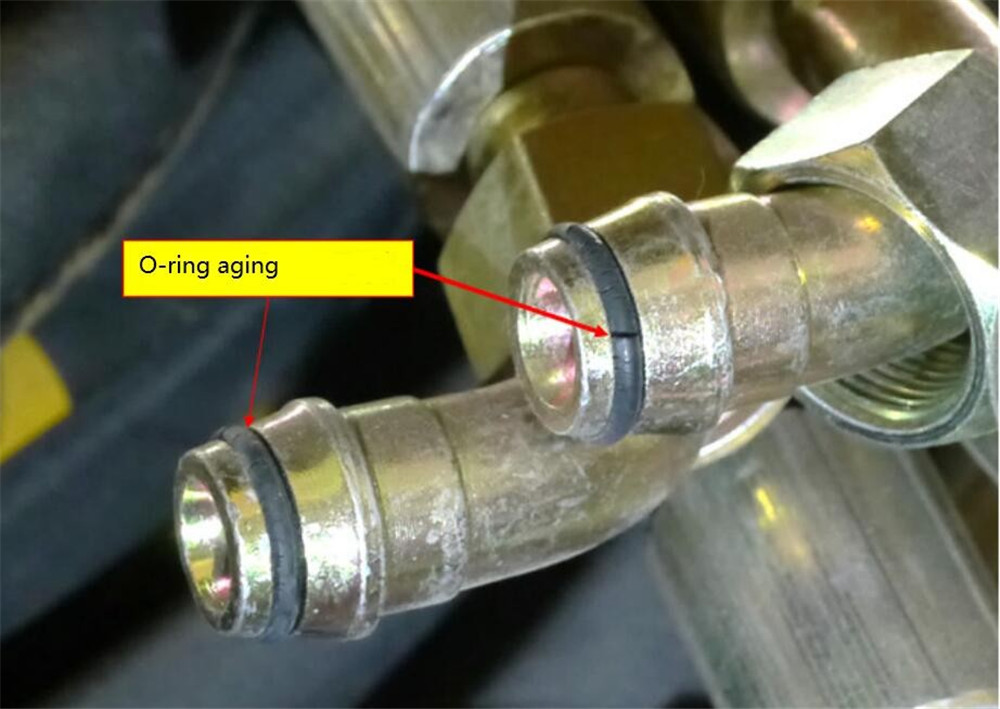

For the crimping hydraulic hose assembly, during the daily warehouse inspection, pay attention to check the storage period of the hydraulic reinforcement hose and the aging of the seal ring. If the storage period is exceeded, the sealing ring of the hydraulic fittings may be aging (if aging, you should purchase another one to replace), otherwise the hydraulic hose fitting may leak oil after being installed on the device.

Post time: Oct-14-2020