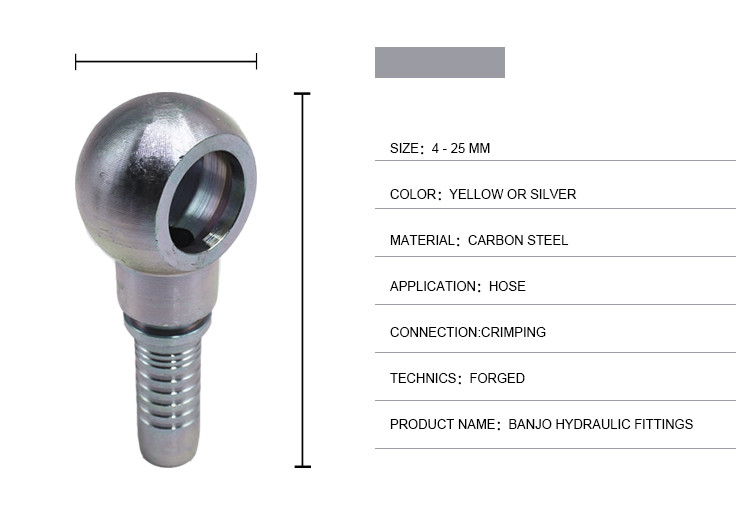

Hydraulic Diesel Fuel Line Brake Parker power Steering Hose Bsp Banjo Fittings

Hydraulic banjo fittings are so named because they are roughly shaped like banjos (the banjo connector we make do not use stringed instruments).

The banjo bolts and fittings is fixed to the end of the fuel line by a hose barb, or brazed to the fuel line. There are several advantages of using banjo accessories-easy assembly, better sealing, reduced space requirements and vibration resistance.

Classic banjo hose fittings for banjo bolts with push-on hose connector for hydraulic or pneumatic connections.

banjo pipe fittings‘ common applications are fuel delivery in automobiles, trucks, agricultural equipment and hydraulic systems

Topa produces bsp banjo and metric banjo. Compared with threaded pipe fittings, the advantage of banjo brake fittings is that brake line banjo fittings do not have to be rotated relative to the main engine fittings. This avoids the risk of damage caused by twisting the hose when tightening the fittings. banjo eye fitting also allows fittings to withstand extremely high pressures, making it a popular choice for fittings and fluid systems.

TOPA Hydraulic provides carbon steel 10mm 12mm banjo fitting (replace 10mm banjo fitting) to hose barb fittings and 316 stainless steel m12 banjo fitting to hose barb fittings in various sizes. The brake hose banjo fittings is a two-piece hose coupling design, which means that a crimp socket is also required to properly drip into the hose assembly. This barbed banjo fittingdoes not contain banjo bolts or copper seals. For more information, contact one of our experienced sales staff