China Cheap price Npt Air Hose Fittings - 20511 Parker carbon steel tractor hose connectors – Topa

China Cheap price Npt Air Hose Fittings - 20511 Parker carbon steel tractor hose connectors – Topa Detail:

Basic Info

Model No.: 20511

Certification: ISO9001

Pressure: High Pressure

Work Temperature: High Temperature

Installation: Welded

Material: Carbon Steel

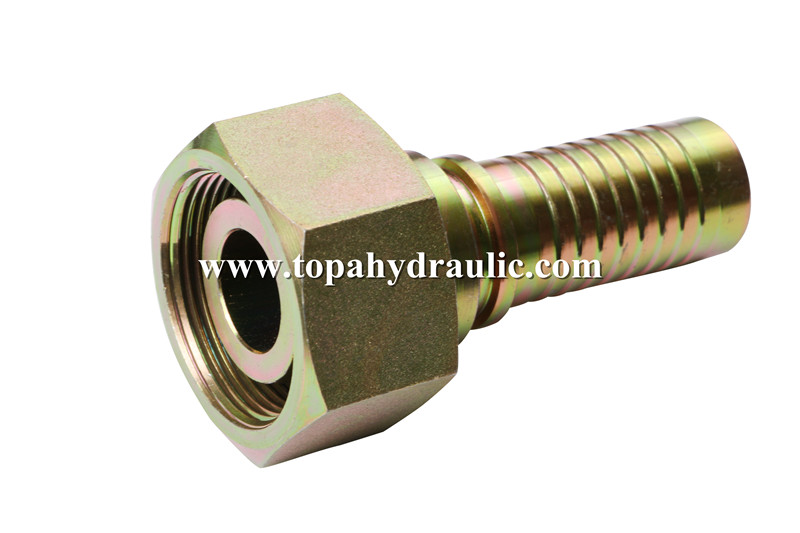

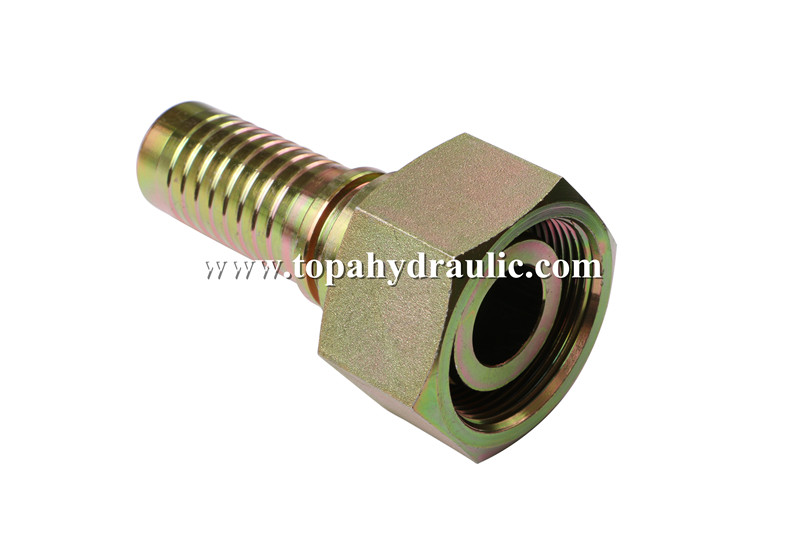

Type: Other, 20511 Parker Hose Connectors

Connection: Female Or Male

Head Code: Hexagon, Round & Forged

Shape: Male Connector, Female Connector, Hex Union, Elbow

Materials: Carbon Steel, Stainless Steel

Size: DN 6MM To 50MM

Standard: Metric

Color: Silver

Surface Treatment: Zinc Plated, Nickle Plating

Name: 20511 Parker Hose Connectors

Thread Type: Internal Thread

Additional Info

Packaging: carton and wooden case

Productivity: 500000 pcs per month

Brand: Topa

Transportation: Ocean,Land,Air,DHL/UPS/TNT

Place of Origin: China

Supply Ability: 500000 pcs per month

Certificate: Hydraulic Fittings ISO

HS Code: 73071900

Port: Ningbo,Shanghai,Tianjin

Product Description

20511 Parker carbon steel tractor Hose Connectors

Hydraulic Adapter Fitting Inculde:

Flat Seal Hydraulic Fitting

Multiseal Hydraulic Adapter Fittings

74°Cone Seal Hydraulic Hose Fitting

24°Cone O-ring Seal Light Hose End Fittings

24°Cone O-ring Seal Heavy Hose Fitting

Standpipe Hose Fitting

Product Description Application

E

HOSE BORE

DIMENSIONS

PART NO.

THREAD E

DN

DASH

TUBE O.D.

C

S

20511-16-04

M16X1.5

6

04

8

1.5

22

20511-18-06

M18X1.5

10

06

10

2

24

20511-20-08

M20X1.5

12

08

12

2.5

27

20511-22-08

M22X1.5

12

08

14

2.5

27

20511-30-12

M30X2

20

12

20

3

36

20511-36-16

M36X2

25

16

25

6.5

41

20511-42-20

M42X2

32

20

30

5

50

High Pressure Hose Fittings Applications: petrochemical industry, the aerospace, railway, automobile manufacturing, vessel, engineering machinery, construction machinery, water conservancy construction, port machinery, wind power generation, special vehicle, printing machinery, engine, metallurgical machinery, mining machinery, Injection molding food machinery, agricultural machinery, machine tool manufacturing, hydraulic system, textile machinery, etc.

Company Information

Hydraulic Fittings connect conductors such as hoses, pipes and tubes in a hydraulic system. Most Hose Fittings have a male and female component that join to form a connection. These Hydraulic Hose Fittings help contain and direct the flow of hydraulic fluid in the conductor while preventing leaks and maintaining pressure. Different hoes end fittings allow designers to change flow direction, the elevation of lines or split flow. Crimping is the most common method for assembling hoses and fittings. Tube fittings are made of many different materials including stainless steel, brass, plastic, Monel and more. Not always, but often fittings match the material of the conductor used in a system.

Our tube fittings products include a wide range of standard : Eaton standard, Parker standard, American standard , custom, and jump size fittings from 1/8″ to 2″ and so on. Virtually any straight or shape style fitting whether tube fitting, pipe fitting, or swivel fitting adapter can be machined in NPT, JIC, ORFS, BSP, BSPT, BSPP, or S. A. E. thread forms and all are meet REACH and RoHS compliant in surface treatments.

Packaging&Shipping

hose connectors Packing Details:

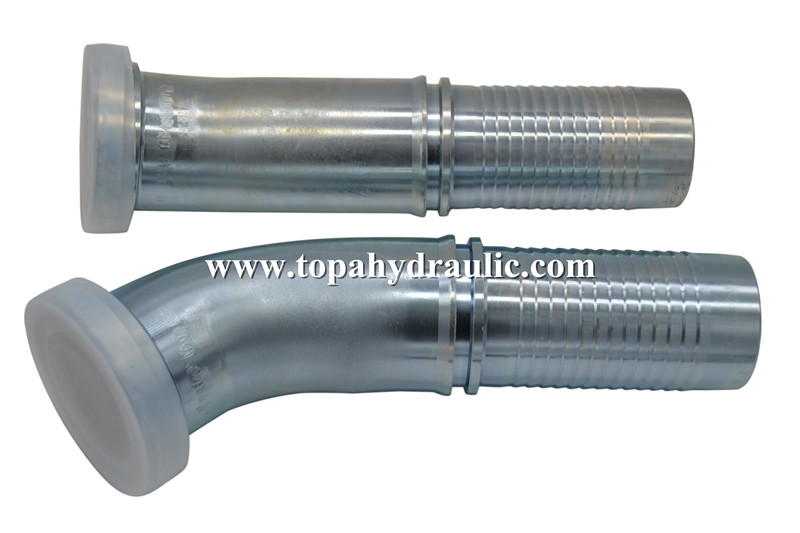

1. our fitting have threads cap, can protect the goods, ensure you can receive goods with all perfect threads.

2. each tube fittings will be covered by plastic cover.

3. then package by carton.

4. 48-52 small cartons tube fittings are in a wooden pallet.

5. our package is perfect, protect fitting clash in transport.

6. Of course, we also allow to do customized package.

Delivery Details :

1. For the sample, we need 3 work days to prepare, delivery by express.

2. For the big order, Generally it is 2-10 days if the goods are in stock. no stock, it is according to order quantity.

3. Usually for 1 20FT, maybe 45 works day.

Inspection

Strict inspection we do during operation

1.We have specialized QC testers to check the products hydraulic fitting quality according to different customers.

2.We have IQC to check the dimensions and surface, quality of the incoming hose fitting material.

3.We have IPQC to inspect full-course during hydraulic hose end fitting processing.

4.We have FQC to inspect all the plating products from outsides and make the 100% inspection before hose connectors the shipments.

we have 8 QC inspect one by one,4 leak detectors and final check before shipment.

QC: Quality Control ( IQC: Incoming Quality Control) ( IPQC: InPut Process Quality Control) , ( FQC: Finish Quality Control)

Advantages

Unique Selling Point

1. Advanced production equipment/Advanced production line and technology.

2. Response within 12 hours.

3. Experienced and well-trained engineers and salesmen.

4. Supporting 200 OEM Clients in Europe and North America.

5. We’ll use our 20 year’s OEM experience to integrate the features you want.

FAQ

Q: Are you trading company or manufacturer ?

A: We are a manufacturer with our own trading company in Shijiazhuang.

Q: How long is your delivery time?

A: Generally it is 2-10 days if the goods are in stock. or it is 20-40 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge,freight charge is for your account. If you make order, we could return freight charge.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance , balance before shippment.

Q: Can you customize products for your customers?

A: Yes, Customized service is one of our core business.

Q:Will you do 100% inspection before Shipment?

A: Our QC will do 100% inspection and we will take the 100% claims if defective.

How To Contact Us?

Looking for ideal 20511 Parker Hose Connectors Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Steel Hose Connectors are quality guaranteed. We are China Origin Factory of Tractor Hose Connectors. If you have any question, please feel free to contact us.

Product Categories : Hydraulic Hose Fitting > Metric Hydraulic Fitting

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for China Cheap price Npt Air Hose Fittings - 20511 Parker carbon steel tractor hose connectors – Topa , The product will supply to all over the world, such as: Hamburg, Bangkok, Pakistan, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.